Why Corrugated

lightweight

Strong

Durable

Versatile

Corrugated packaging blends structural rigidity with cushioning features to save heavy or fragile contents from harm or damage.

Corrugated packaging is clean and lightweight, reduces transport costs with fewer loads, less fuel and lesser emissions.

Corrugated packaging sells your goods with great impact printing and graphics that drive brand awareness and item preference to enable close the sale.

Corrugated packaging is renewable, more than 90% percent is recovered and it can be recycled to make fresh boxes or other paper items.

If you are wondering what a corrugated box is, then we can come up with a single definition. When a flute paper, which is made by compressing the Kraft containerboard in the shape of S arch and then sandwiched between the linear board with the help of the adhesive, this sheet is called a corrugated sheet and the box made out of it is called a corrugated box.

Well, there cannot be one particular answer to this as there are many advantages of using a corrugated box. This lightweight box can provide enough protection against the packed goods. We can look at the following points to understand the advantage of using a corrugated box.

Now that you have got an idea about a corrugated box, let’s dig deeper into different types of corrugated boxes used in different sectors of industries according to their durability, the protection they provide and the capacity of handling the weight.

There are mainly four types of corrugated box – single-phase corrugated box, single-wall corrugated box, double-wall corrugated box, triple-wall corrugated box. We will have a look at the difference between them and their applications in various industries.

Single-phase corrugated

This type of corrugated sheet consists of a single flute and one or two sheets of linear board. The flute is glued to the linear board. Single-phase corrugated boxes are usually sold in the form of sheet rolls and are most commonly used to wrap around products for protection or cushioning.

Single wall corrugated box

This type of corrugated box consists of one sheet of corrugated medium which is glued and placed between two sheets of liner board. This type of corrugated box has multiple uses in retail industries and as shipping boxes.

Double wallboard

Double walled corrugated boxes consist of a two-layer of corrugated medium glued between three layers of liner board. Hence, it makes the box more rigid and can be used for packaging of heavy products or products which are more delicate. This type of corrugated boxes is widely used in shipping of electronic products.

Triple wallboard

One which is the strongest of all types of corrugated boxes consists of three layers of corrugated medium and four-layer of liner board. This Triple wall corrugated boxes are mainly used in packaging of industrial parts due to their durability and higher burst strength.

If you are having a business like a franchise of a pizza shop and looking for corrugated pizza box for packaging or having a custom handmade product to be shipped to your customer or anything else which includes corrugated box in it. Then you must know that what to look at before you choose which type and style of corrugated box among them is the most suitable one for you.

To check this we need to know that where would be this corrugated box is going to be used and once we are familiar with it we can go through a checklist to follow up and get the most suitable box for our need.

What does GSM in corrugated box mean?

GSM in corrugated box means Gram per square meter which means the amount of ply used in building the corrugated box. The higher GSM Shows that the more durability of the corrugated box and higher bursting strength.

What is the burst factor in the corrugated box?

Bursting strength defines the amount of pressure the paper can tolerate before it ruptures. In a corrugated box, the no. of ply and flute paper increase the durability of the carton and thus it increases the bursting strength.

Which products can be packaged in the carton?

As there are many styles of corrugated box available in the market you should choose the one which is most suitable for your particular industry.

Which grade of corrugated box will my package require?

The grade of corrugated box is an important factor if you want your product to be safely delivered to your customer. This grade can be decided by checking the Composition, Type of paper used, GSM, and Type of Flute.

Where would be the box used?

This is an important question to ask yourself before ordering a corrugated box – Whether you want to use it for packaging of consumer products or if it is needed for shipping purposes. Because it will help you to decide which type, style and printing you will be using on them.

Which printing method is best for you?

Once you have decided the style and type of corrugated box, now you need to decide the process of printing that you want to use on the corrugated box. If it is for consumer products, then you can go for digital printing and lithography. If it is for shipping, then you can go for flexo and if it is for custom made then you can choose silkscreen.

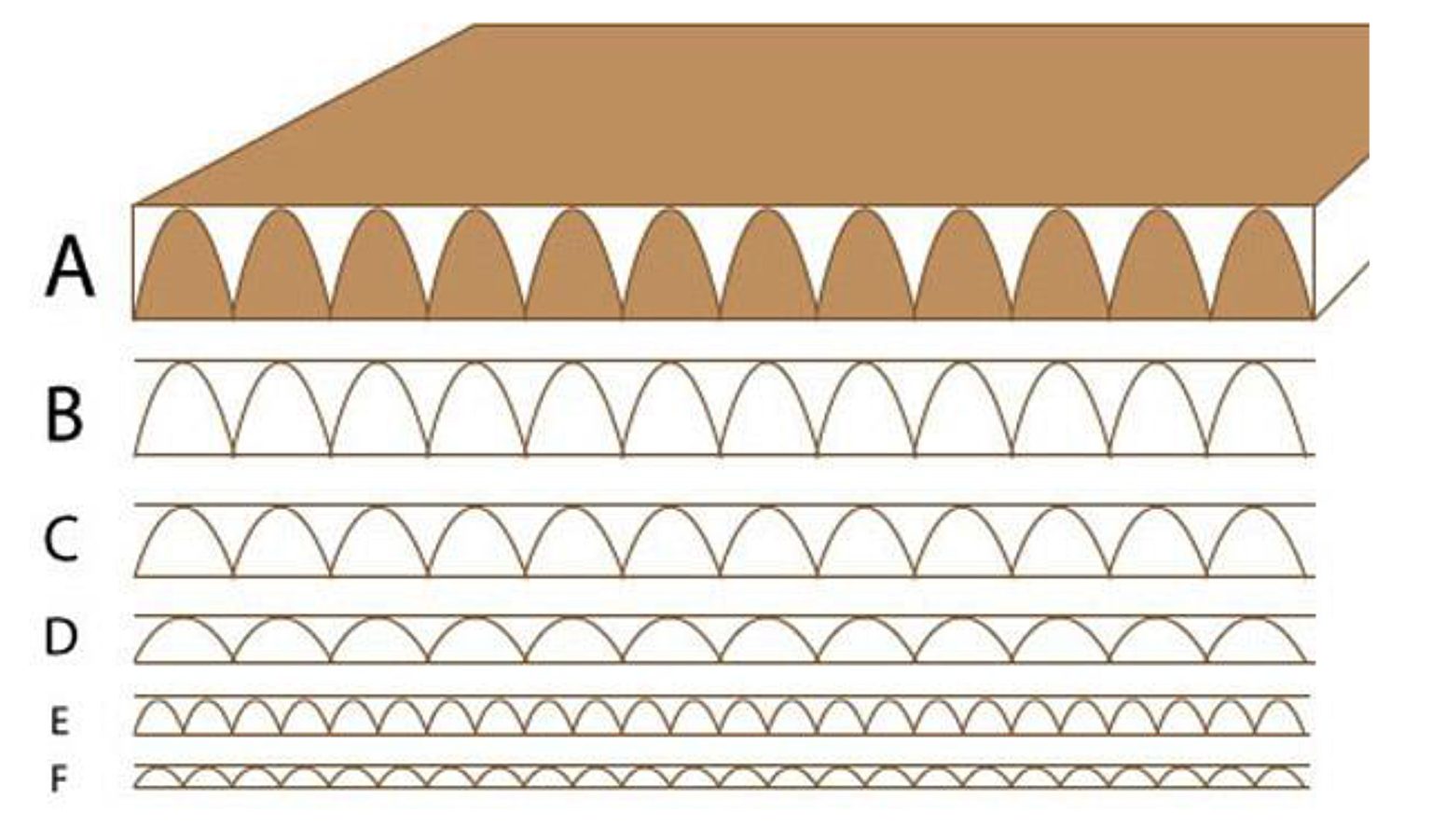

What does a flute mean in a corrugation? Well, different types of flutes are used in corrugated boxes among which the most commonly used is Flute C which is used in more than 80% of corrugated boxes. The different types of flute have been made for different purposes.

A-Flute (36 Flutes / Foot)

A-Flute, the original flute, is the highest flute size, and therefore, when combined with an inner and outer facing, is the thickest. With 36 flutes to the foot, A-Flute makes the most of corrugated’s cushioning and stacking properties for fragile and delicate items. Because A-Flute offers excellent stiffness qualities and short column crush resistance, it has a broad range of uses.

B-Flute (49 Flutes / Foot)

B-Flute, the second flute size adopted by the corrugated industry, has lower arch heights than A and more flutes per foot (49). This means that the medium contacts and supports the liners at a greater number of points, providing a stiff, flat surface for high quality printing and die cutting and with excellent crush resistant properties. B-Flute is also preferred for high speed, automatic packing lines and for pads, dividers, partitions and other forms of inner packing. Complex die cuts and beverage trays are excellent applications for B-Flute as are can cases, wrap-around blanks, glass-to-glass packs and slipsheets. B-Flute is generally combined with lightweight liners but can be used with heavier facings if the need arises. Common uses are food packaging, retail packaging, litho laminating, POP (point of purchase) displays, die cut inserts, and custom printed packaging.

C-Flute (41 Flutes / Foot)

B-Flute, the second flute size adopted by the corrugated industry, has lower arch heights than A and more flutes per foot (49). This means that the medium contacts and supports the liners at a greater number of points, providing a stiff, flat surface for high quality printing and die cutting and with excellent crush resistant properties. B-Flute is also preferred for high speed, automatic packing lines and for pads, dividers, partitions and other forms of inner packing. Complex die cuts and beverage trays are excellent applications for B-Flute as are can cases, wrap-around blanks, glass-to-glass packs and slipsheets. B-Flute is generally combined with lightweight liners but can be used with heavier facings if the need arises. Common uses are food packaging, retail packaging, litho laminating, POP (point of purchase) displays, die cut inserts, and custom printed packaging.

E-Flute (95 Flutes / Foot)

E-Flute has the greatest number of flutes / foot, which gives it the greatest crush resistance and the flattest surface for high quality printing applications. The thin board profile of E-Flute (it is one-fourth the thickness of C-Flute) reduces box size and saves storage space. Because of its thin profile and cushioning properties, E-Flute can substitute for conventional folding cartons or solid fiber containers. Examples of E-Flute applications include boxes for cosmetics, glass, ceramic items and delicate instruments. Another growing end-use is the pizza box: a cost effective, printable container for product protection.

F-Flute (128 Flutes / Foot)

F-Flute, the newest flute, is nearly half the thickness of E-Flute and is a popular choice in the corrugated industry. The idea for F-flute originated in Europe to reduce the fibre content of packaging. Converting to F-Flute can reduce the total amount of fibre in packaging. F-flute makes a more rigid box and sends less wastage. F Flute will give your box a very high value look and provide your packaging with solid structural integrity. Common uses are custom printed boxes, printed corrugated boxes, retail packaging, and POP displays. So, we can see that corrugated packaging has evolved with the time and new “FLUTE” types that have emerged with time have provided a great deal of flexibility to the corrugated industry. This has helped corrugated products being adopted to pack a wide range of products and will continue to do so in future.

© Copyright Devas Corrugating Industries.